In 2014 delsa has expanded its product range through the acquisition of Tampograf, a historic firm which operates in the pad printing industry, since 1968.

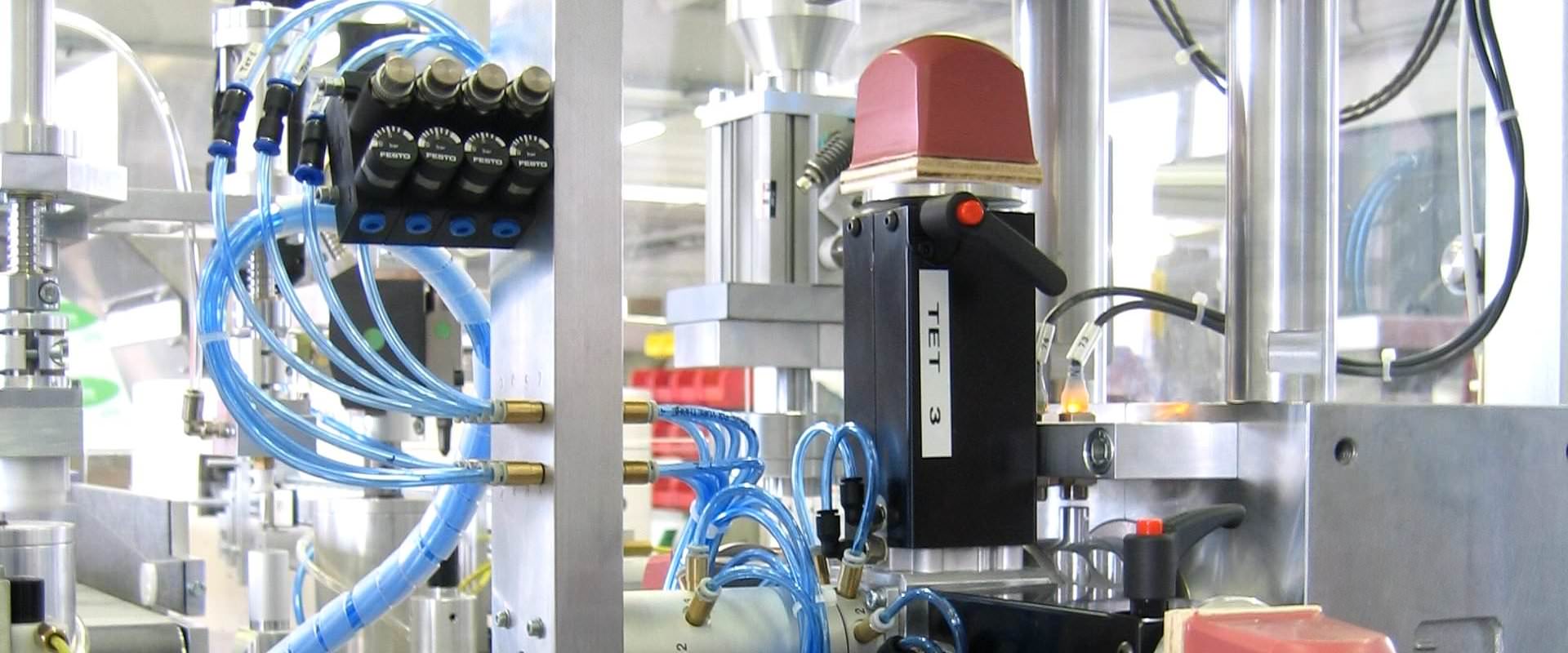

This acquisition has allowed delsa to offer the customer both the classic pad printing machine models and the integration of pad printing heads on its own automatic machines.

delsa offers together with the construction of pad printing machines the supply of accessories and tools related to tampography, such as:

• silicon pads;

• photopolymer clichés;

• bromographs for the clichés printing;

• inks, catalysts and thinners.

What is pad printing?

THE TAMPOGRAPHY or PAD PRINTING

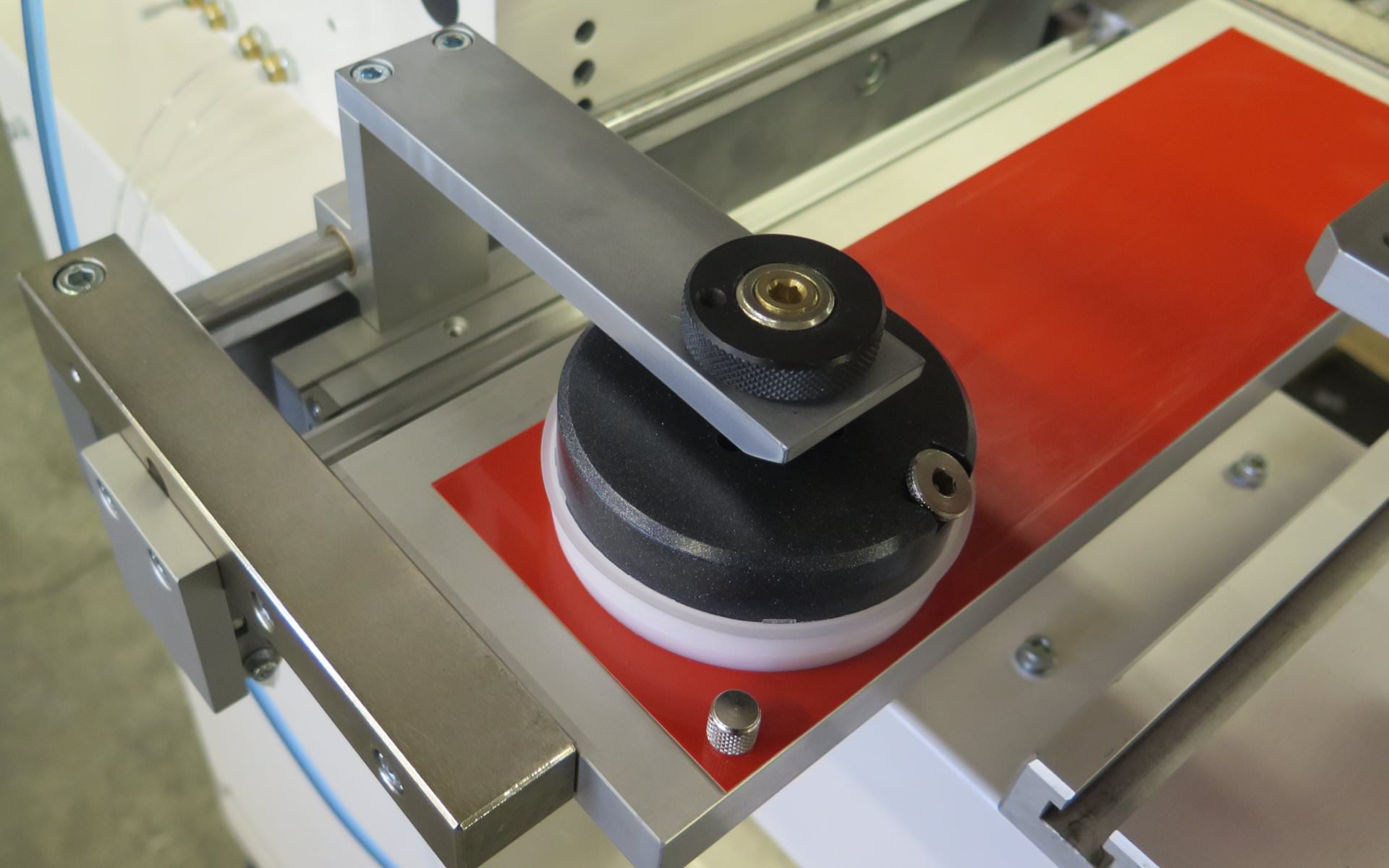

is a printing technique that uses a silicone pad to pick the paint from a cliché and then transfer it to the surface to be decorated. The cliché is normally made up of a photopolymer or steel plate in which a groove is made and which reproduces the graphic to be transferred.

At each printing cycle the cliché is inked through an airtight cup, which slides over its engraved area and then retracts, scraping away the excess paint.

The ink stays on the cliché only in the areas corresponding to the graphics to be transferred. The pad can now get the ink, move over the piece to be decorated and then lower once again, transferring the ink to the surface to be decorated.

Here are the main benefit offered by pad printing compared to other decoration techniques:

• flexibility:

by selecting the correct pad form it is actually possible to decorate even details with very complex and irregular shapes.

The decoration fastness on the material to be printed only depends on the choice of the most suitable paint here's why, through the same technique, it is possible to decorate items made of different materials: plastic, glass, ceramic, wood, metal, etc .;;

• fast drying paint:

thanks to the reduced thickness of the transferred paint layer, the drying fastly takes place and it is possible transferring multi-color graphics with a series of consecutive print with no intermediate pauses of drying;

• possibility of transferring quadrichromic graphics:

it is possible to obtain shaded graphics able to reproduce any type of image through the execution of 4 consecutive prints with the CMYK basic colours;

• less intervention required:

the paint is not exposed to air, but instead stored within an airtight cup, this allows to optimise the working times after the preparation of the paint, avoiding frequent rifills and several dilutions.

THE TAMPOGRAPHY or PAD PRINTING

is a printing technique that uses a silicone pad to pick the paint from a cliché and then transfer it to the surface to be decorated. The cliché is normally made up of a photopolymer or steel plate in which a groove is made and which reproduces the graphic to be transferred.

At each printing cycle the cliché is inked through an airtight cup, which slides over its engraved area and then retracts, scraping away the excess paint.

The ink stays on the cliché only in the areas corresponding to the graphics to be transferred. The pad can now get the ink, move over the piece to be decorated and then lower once again, transferring the ink to the surface to be decorated.

Here are the main benefit offered by pad printing compared to other decoration techniques:

• flexibility:

by selecting the correct pad form it is actually possible to decorate even details with very complex and irregular shapes.

The decoration fastness on the material to be printed only depends on the choice of the most suitable paint here's why, through the same technique, it is possible to decorate items made of different materials: plastic, glass, ceramic, wood, metal, etc .;;

• fast drying paint:

thanks to the reduced thickness of the transferred paint layer, the drying fastly takes place and it is possible transferring multi-color graphics with a series of consecutive print with no intermediate pauses of drying;

• possibility of transferring quadrichromic graphics:

it is possible to obtain shaded graphics able to reproduce any type of image through the execution of 4 consecutive prints with the CMYK basic colours;

• less intervention required:

the paint is not exposed to air, but instead stored within an airtight cup, this allows to optimise the working times after the preparation of the paint, avoiding frequent rifills and several dilutions.

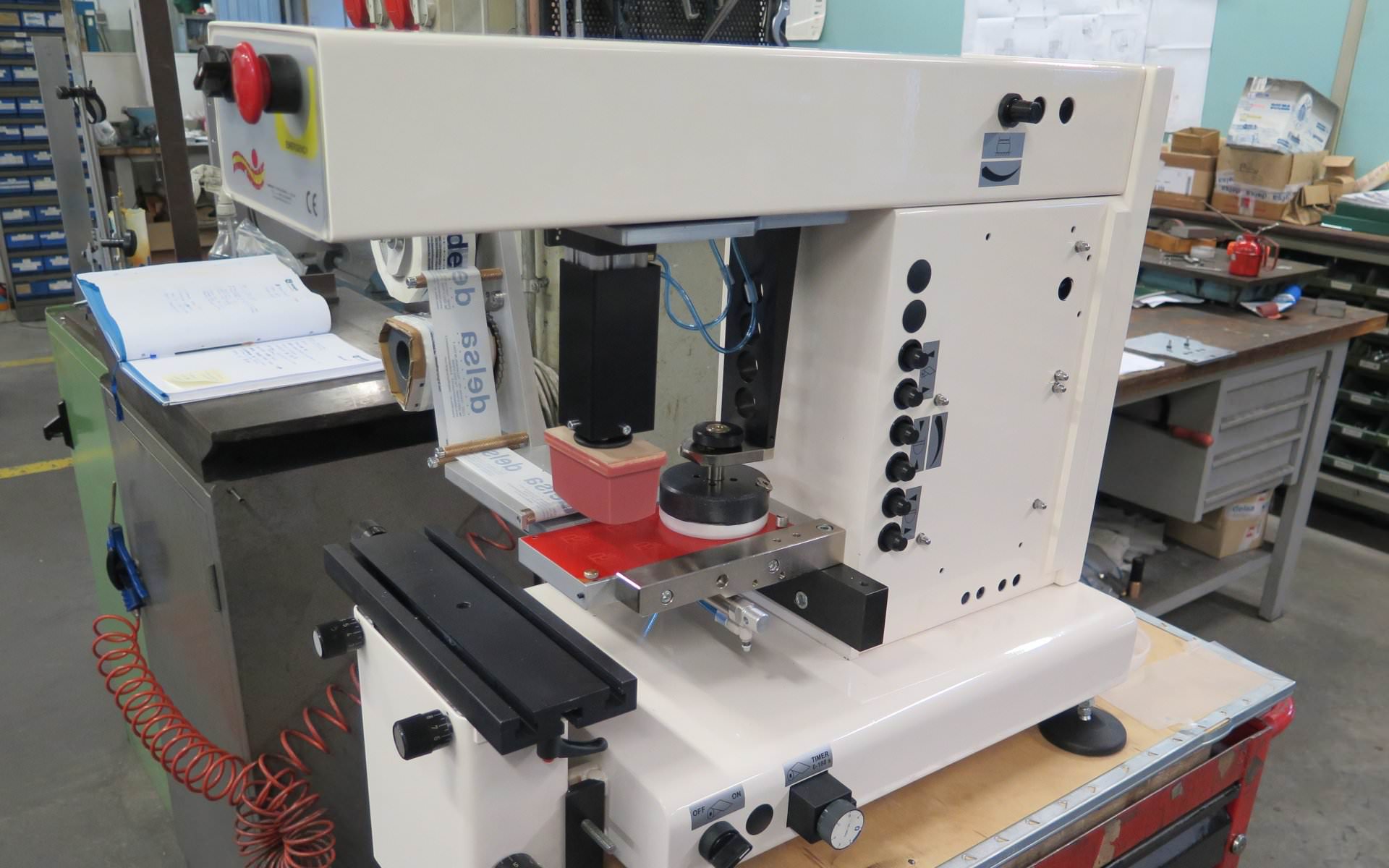

The classic Tampograf machine produced by delsa are semi-automatic:

manual loading / unloading by an operator is required.

The decoration cycle is automatically carried out, after the operator has pressed Start.

The main features of delsa tampography machine are:

• Semi-automatic functioning

• Change of colour and cliché within a few seconds

• Quick setup without using any tools

• Rugged construction and solvent-resistant powder coatings

• Fully pneumatic systems (6 bar)

• Explosion-proof

• Very intuitive operations

• Precision positioning cliché to avoid registration problems

• Patented airtight inkwell with two-lip ceramic pad printing rings, with double working life

• Special pad which can print on any level (even below the cliché level)

• Multi-pad models: independent pads that allow stamping even on different levels

• Equipped machine ready for stamping even after long periods of inactivity.

The selection of the machine model mainly depends on:

• the maximum size of the graphics you want to transfer

• the number of colours ( 1,2,or 4)

• the size of the piece to be decorated.

Smallest machines are very easy to use as they only require compressed air supply, for example from a small compressor. Power supply is not required, as the movements of these machines are generated only by pneumatic actuators and a pneumatic board manages the operating sequence.

Larger machines need a power supply instead.

Pad printing machines

TG 30

Small series created to meet the needs of printing on small and medium-sized high-speed surfaces, with manual loading and unloading.

Tampograf technology guarantees a minimum solvent evaporation allowing the ink to stay within the machine for long periods, ready for printing.

MODELS:

TG30N1 1 colour printing

TG30N2 2 colours printing

SPECIFICATIONS:

• Hourly production ( adjustable ): about 2200 p/h

• Ink-cup: diameter 90 mm

• Printing max. diameter: 85mm with patented airtight inkwell

• Cliché max. diameter: 93x200 made of plastic or steel

• Pad holder: magnetically attached to the slide, it allows rapid set-up

• Work cycles: single; continuous, ink mixing

• Pad strength: 400 N

• Pad stroke: 55 mm. self-regulating

• In/Out: featured by cycle end and piece presence detectors integrated in the machine

• Power supply: 6 bar compressed air

• Pieces shelf: x, y, z and r cross table for fine adjustments

• Sizes: 240 x 550 x 700 mm.

SPECIFICATIONS:

• Hourly production ( adjustable ): about 2200 p/h

• Ink-cup: diameter 90 mm

• Printing max. diameter: 85mm with patented airtight inkwell

• Cliché max. diameter: 93x200 made of plastic or steel

• Pad holder: magnetically attached to the slide, it allows rapid set-up

• Work cycles: single; continuous, ink mixing

• Pad strength: 400 N

• Pad stroke: 55 mm. self-regulating

• In/Out: featured by cycle end and piece presence detectors integrated in the machine

• Power supply: 6 bar compressed air

• Pieces shelf: x, y, z and r cross table for fine adjustments

• Sizes: 240 x 550 x 700 mm.

TG 80

Small, extra-flexible series created to meet the needs of printing on small surfaces and usable with manual loading and unloading for small / medium product series or on automatic lines for large series.

MODELS:

TG80N1 1 colour printing

TG80N2 2 colours printing

TG80NT transverse cup

TG80N135 big-size transverse cup

SPECIFICATIONS:

• Hourly production ( adjustable ): about 1400 p/h

• Ink-cup: diameter. 90 mm

• Printing max. diameter:40,55 or 88 mm / with patented airtight inkwell

• Cliché max. diameter: 93x200 /made of plastic or steel

• Pad holder: magnetically attached to the slide, it allows rapid set-up

• Work cycles: single; continuous,actuated from an external line

• Pad strength: 800 N

• Pad stroke: 55 mm. / self-regulating

• In/Out: featured by cycle end and piece presence detectors integrated in the machine

• Power supply: 6 bar compressed air

• Pieces shelf: x, y, z and r cross table for fine adjustments

• Sizes: 400x 700 x 700 mm.

SPECIFICATIONS:

• Hourly production ( adjustable ): about 1400 p/h

• Ink-cup: diameter. 90 mm

• Printing max. diameter:40,55 or 88 mm / with patented airtight inkwell

• Cliché max. diameter: 93x200 /made of plastic or steel

• Pad holder: magnetically attached to the slide, it allows rapid set-up

• Work cycles: single; continuous,actuated from an external line

• Pad strength: 800 N

• Pad stroke: 55 mm. / self-regulating

• In/Out: featured by cycle end and piece presence detectors integrated in the machine

• Power supply: 6 bar compressed air

• Pieces shelf: x, y, z and r cross table for fine adjustments

• Sizes: 400x 700 x 700 mm.